BMW’s M division is preparing a discreet but significant change: it will stop using carbon-fibre in favour of a composite based on natural fibres, primarily flax.

This innovative material, already proven in competition, could soon find its way into next-generation M models, including the future M3 built on the Neue Klasse platform, expected in 2026.

| Photo: BMW

From track to road: Flax to lighten M cars

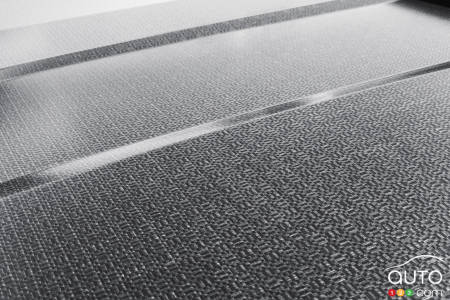

Developed by Swiss company Bcomp and tested in Formula E, DTM and GT4 racing, the composite uses flax stalks and seeds to form a light, renewable and high-performance fibre. BMW says its use can reduce CO2 emissions during manufacturing by up to 40 percent, compared to traditional carbon-fibre.

Crucially, the material retains the necessary rigidity to meet road safety standards, while lightening the vehicle and improving mass equilibrium — a key issue for any M model.

Mature technology, but not yet for M5

BMW says the flax composite has reached maturity for series production, but it will be some time before it appears on larger models like the M5. The next logical test bed would be the M3 Neue Klasse, the M350 variant of which has just been teased by BMW.

World premiere at Nürburgring 24h

The first appearance of the new technology is this weekend at the Nürburgring 24 Hours, on the official M4 GT4. Components like the rear diffuser and the air intake on the bonnet will feature this new material. BMW is also considering its integration into the interior, particularly on the dashboard, door panels, and the M steering wheel.

Multiple avenues towards greater sustainability

While continuing its use of 6-cylinder and V8 engines, market realities oblige, BMW is also betting on hydrogen (in partnership with Toyota) and the integration of recycled materials to reduce its overall environmental footprint.

| Photo: BMW